Heavy Duty Plug Types Technical Data

| C/US CSA | Product Name | NEMA | UL | CSA | C/UL | Catalog # |

|---|---|---|---|---|---|---|

|

BFP Plug 6-15P |

|

X | X | X | KK3000 |

|

BFP Plug 6-15P Cord Grip |

|

X | X | X | CG3000 |

|

BFP Plug 6-20P |

|

X | X | X | KK4000 |

|

BFP Plug 6-20P Cord Grip |

|

X | X | X | CG4000 |

|

BFP Plug 5-20P |

|

X | X | X | KK5000 |

|

BFP Plug 5-20P Cord Grip |

|

X | X | X | CG5000 |

|

BFP Plug 5-15P |

|

X | X | X | KK6000 |

|

BFP Plug 5-15P Cord Grip |

|

X | X | X | CG6000 |

Heavy Duty Power Cord Technical Data

| Plug Type | Wire | Amps | Voltage |

|---|---|---|---|

| NEMA 6-15P BFP NEMA 6-15P CG BFP | 18/3, 16/3, 14/3, 12/3 | 10, 13, 15, 15 | 250 |

| NEMA 6-20P BFP NEMA 6-20P CG BFP | 18/3, 16/3, 14/3, 12/3 | 10, 13, 15, 20 | 250 |

| NEMA 5-20P BFP NEMA 5-20P CG BFP | 18/3, 16/3, 14/3, 12/3 | 10, 13, 15, 15 | 125 |

| NEMA 5-15P BFP NEMA 5-15P CG BFP | 18/3, 16/3, 14/3, 12/3 | 10, 13, 15, 15 | 125 |

** Available in a variety of wire types **

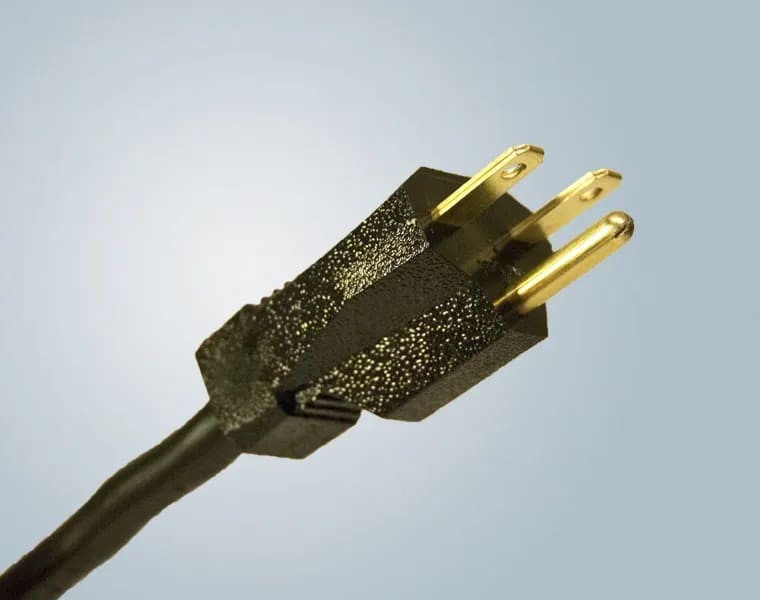

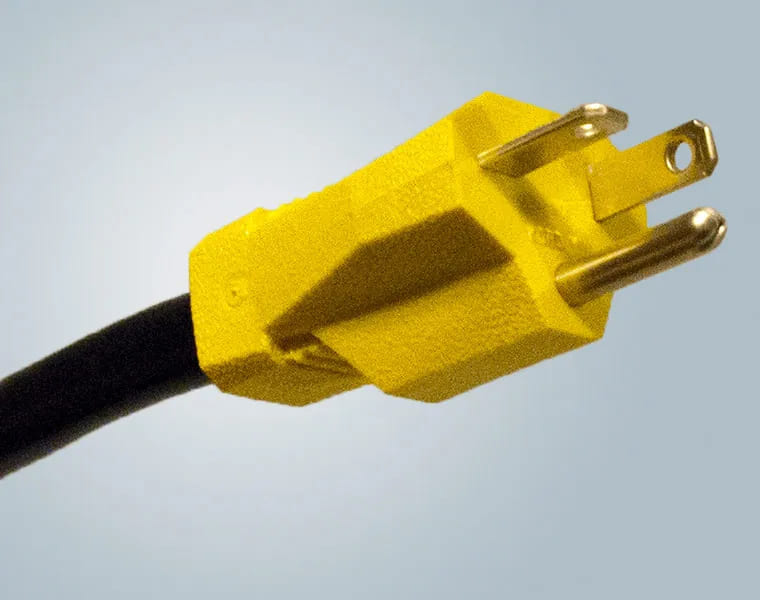

Advantages of Kord King Heavy Duty Power Cords

Kord King heavy duty power cords are designed for high usage, rough environment, industrial and commercial applications. The head is molded with large flats and deeply contoured ridges that provide a non-slip grip. A heavy molded strain relief shroud is used where the cord enters the plug, which is ideal for tough work areas such as construction sites, machine shops and warehouses.

What is a Heavy Duty Power Cord?

Heavy duty power cords are capable of supporting high voltage usage and come in a variety of end configurations. They are distinguished by their grounding pin that directs stray currents to the ground. The length of heavy duty power cords determines the gauge of wire used to manufacture them, with longer cords having a heavier gauge wire. All Kord King heavy duty power cords are U. L. listed and C. S. A. approved.

Requirements

A heavy duty power cord is defined by the number of amps required by heavy duty equipment or appliances, which are between 10 and 15 amps. The gauge of the wire used to manufacture the heavy duty power cords, ranges between 10 AWG and 18 AWG. Devices requiring higher amps, require wires with heavier gauges. To be considered as a heavy duty power cord, it must contain a third prong; this prong provides additional shock protection to both appliances and people.

Testing of Heavy Duty Power Cords

Kord King heavy duty power cords are put through a wide range of tests to ensure their conformance to U.L., C.S.A. and NEMA standards. The nature of the use for heavy duty power cords necessitates close adherence to testing standards and cord regulations. Every Kord King heavy duty power cord meets not just national and international standards but, additionally, the more-stringent quality standards of Kord King. To receive the Kord King standard of approval, their heavy duty power cords must also pass various tests including the Kord King:

- Dielectric Voltage-Withstand Test

- Insulation Resistance Test

- Flexing Test

- Forces Necessary to Insert and to Withdraw Connector Test

- Temperature Test

- Strain Relief Test

- Impact Resistance Test

Types of Heavy Duty Power Cords

Kord King heavy duty power cords are available in a variety of end types and pin configurations. They are U. L. listed and C. S. A. approved and are molded in several colors. They come in lengths to fit any standard application including:

- NEMA 6-15P BFP NEMA 6-15P CG BFP

- NEMA 6-20P BFP NEMA 6-20P CG BFP

- NEMA 5-20P BFP NEMA 5-20P CG BFP

- NEMA 5-15P BFP NEMA 5-15P CG BFP

More importantly, Kord King can custom engineer heavy duty power cords to meet your specific needs. To learn more about the products they carry, the services they provide, and the values that make Kord King, “The King of Cords,” as the largest manufacturer of power cords in the United States, please visit us at KordKing.com